BNSF’s Northtown facility: A legacy of innovation

By MIKE PAGEL

Staff Writer

A loaded hopper car slowly rolled from a man-made hump elevated 21 feet into the Minneapolis sky. As the hopper came to rest coupled with another railcar on the classification tracks below, it became the first of millions to be classified at this impressive rail facility.

This scene was from November 1974 at Northtown, BNSF predecessor Burlington Northern Railroad’s (BN) flagship electronic classification yard, where railcars are sorted and grouped to build outbound trains.

Today, our Northtown facility and our employees there are as vital to our operations as they were 50 years ago. In addition to the hump yard, Northtown also includes a locomotive service and repair shop and a freight car repair shop. In all, Northtown is home to roughly 500 BNSF employees.

Recently, Northtown celebrated its golden jubilee with employees sharing a meal and stories from the past and receiving commemorative 50th anniversary coins. The event included newly hired up to 44-year employees. They also decorated the walls of the hump tower with old historic photos of former employees from Northtown.

The facility’s initial planning and construction began in the early 1970s on the heels of the BN merger that combined the Great Northern Railway (GN), the Northern Pacific Railway (NP), the Chicago, Burlington and Quincy Railroad (CB&Q) and the Spokane, Portland and Seattle Railway (SP&S).

“The Minneapolis-St. Paul area signified a key geographic location for these railroads that had come together, dating back to the James J. Hill days,” said Nick O’Connell, assistant superintendent. “Northtown was just a logical destination for the classification of all these cars because of the amount of rail traffic through that region.”

Prior to the development of Northtown, the GN, the NP and the CB&Q operated 11 separate yards and 23 interchange points. With the merger, it seemed only logical to consolidate operations, which would drive efficiencies in service time, manpower and expense.

The former NP flat yard became the recommended site for Northtown because of its availability of additional land, access to switching areas, good labor supply and accessibility to interchanges. Construction began in 1971 and progressed steadily through winters with minimal interruption of train traffic. The classification of cars using the hump began in November 1974, and the yard was completed in 1976 at a cost of about $43 million – equal to about $285 million today.

The operational efficiencies of Northtown were evident almost immediately. After the yard’s completion, railcars moved through the Twin Cities terminal area about 18 hours faster on average than before.

Thanks to its planners, the early days of Northtown featured some cutting-edge technology designed to make operations safe and smooth.

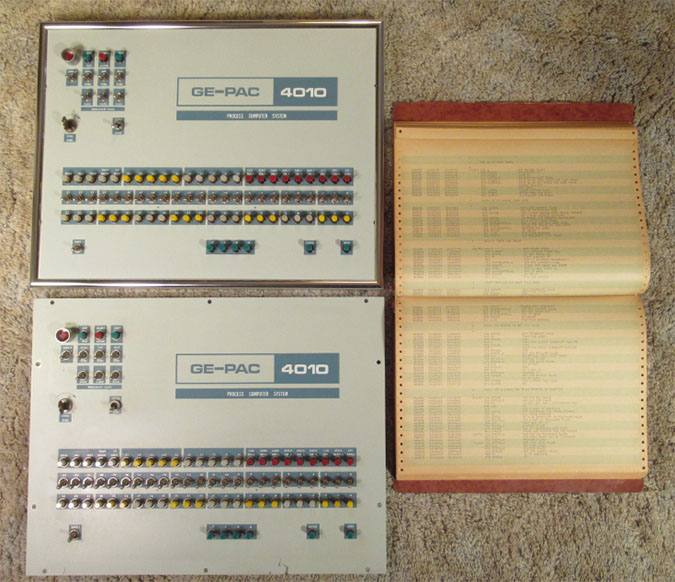

A pair of General Electric computers was installed as a key controlling element of the hump. They were highly configurable digital and analog input-output equipment for interfacing with the yard equipment and had specialized instructions for performing yard control functions. Additionally, “retarder control” software was developed to measure the rolling resistance of the railcars, distance to couple out each track, and weather and other conditions that could affect the cars’ roll down the hump. The software applied this data to calculate desired exit speeds out of the retarders and to ensure safe coupling speeds.

“As I think about Northtown through the years, two things come to mind – innovative technology and the people who make this place go,” said O’Connell, who has been in and around Northtown since 2005. “It’s always been revolutionary.”

Today, Northtown remains a significant cog in the wheel of BNSF operations, processing an average of about 1,500 cars a day. It’s the third-largest hump yard on the network. Situated on the Northern Transcon between Chicago and the Pacific Northwest, Northtown is a major gateway for agricultural commodities heading west for export, as well as industrial products like lumber moving east, and consumer products making their way to surrounding states.

Happy anniversary, Northtown! Here’s to the next 50 years of innovative success.

DID YOU KNOW?

Here are some facts and figures about the initial construction of Northtown’s hump yard in 1974:

- Built on 250 acres of land in Minneapolis, Fridley and Columbia Heights, Minnesota

- Cost: about $43.9 million

- 105 miles of track

- 63 classification tracks with capacity of 2,175 cars

- Hump height: 21.5 feet

- Normal humping speed: 2.5 mph

- Designed to classify 1,000 cars in each eight-hour shift

- Switches equipped with electric snow melters